Brightening the future with invisible light ― Stanley continues to add new value with ultraviolet and infrared LEDs

Invisible ultraviolet and infrared light holds great promise as a key to resolving many social and environmental problems. Stanley Electric is contributing to the expansion in applications of ultraviolet and infrared light LEDs. This article introduces Stanley’s high-power ultraviolet and infrared LEDs designed to take on challenges faced by cities and the natural environment.

Light ― life would not exist without it. You may imagine light is something bright and shiny, but human eyes can only see a part of it, and the remaining invisible light functions in various ways.

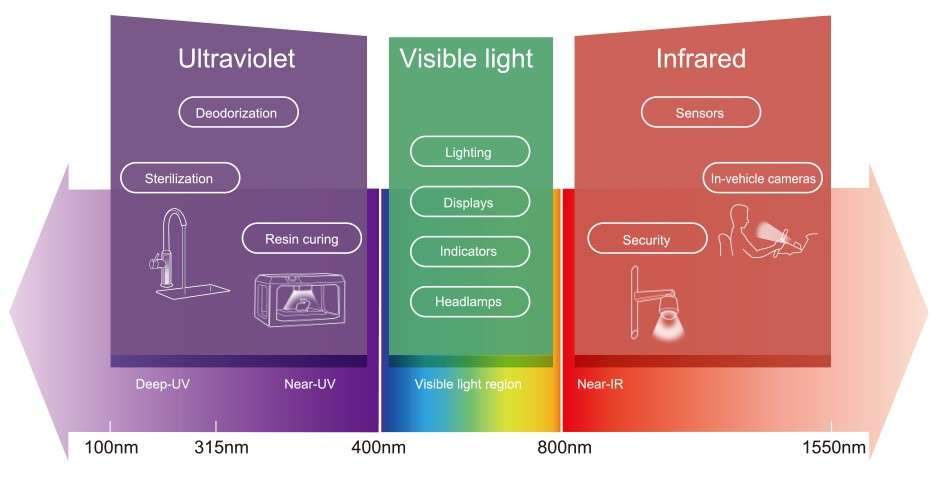

Light defined as visible to the human eye is light with a wavelength between 400 nm and 800 nm, while light of all other wavelengths is known as invisible light. This invisible light is divided into two broad categories of ultraviolet, with wavelengths shorter than visible light, and infrared, with longer wavelengths. Ultraviolet and infrared light have many different effects that people have used since ages past.

The most well-known effect is sterilization using ultraviolet light. People line-drying clothes or drying food products in sunlight have unknowingly used this sterilization effect of ultraviolet light. Medical instruments and food are also disinfected using light sources such as UV light emitting lamps.

Infrared light is well-known for its use in TV and air conditioner remote control signals and as a light source for surveillance cameras and various types of sensors.

Although they have been in use for a long time, ultraviolet and infrared light are now of even greater interest due to the enormous evolution in ultraviolet and infrared LED development.

Ultraviolet LEDs enable sterilization and other applications of ultraviolet light in various settings

LEDs are now replacing ultraviolet light sources in the same way that they have replaced light bulbs and fluorescent tubes. With the advent of LEDs that emit ultraviolet light, these are displacing ultraviolet lamps, which have been the conventional germicidal lamp. The advantages of LEDs are that they are smaller, consume less power and are longer-lived than ultraviolet lamps, making them promising for a wide variety of ultraviolet applications.

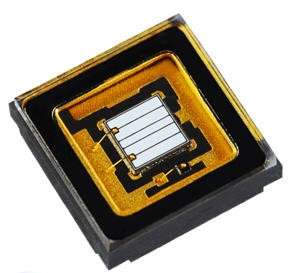

The YDU1105EAE, our deep-UV LED with a wavelength of 265 nm, boasts an industry-leading light output level of 50mW

The YDU1105EAE, our deep-UV LED with a wavelength of 265 nm, boasts an industry-leading light output level of 50mWAs a worldwide manufacturer of automotive lamps and LEDs, Stanley has developed and marketed various types of light sources, including cold cathode ultraviolet lamps. The company is now actively developing ultraviolet and infrared LEDs, positioning “invisible light” as “a solution for the future social and environmental challenges.”

One example of social challenges that could be resolved by invisible light is the global water demand increase caused by population increase and industrial development. While water is a limited resource, human beings need a stable supply of safe water. Considering hundreds of people are still suffering from poor water environments today, water sterilization using ultraviolet rays will be of help to solve such a worldwide social challenge. Also, since UV light resin curing is used by many manufacturers, achieving more efficient LEDs can contribute to reduced energy consumption. That’s why Stanley is rapidly expanding its lineup of “invisible light” LED products, aiming to maximize the power of light by providing the world with light sources that provide reassurance, safety and energy saving.

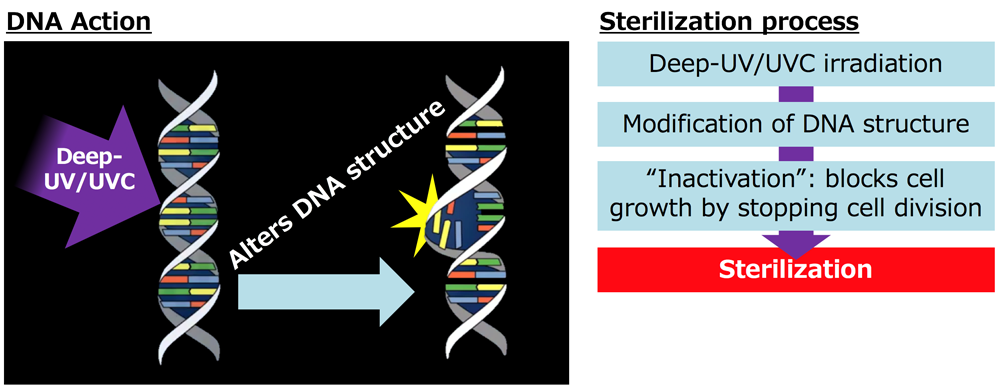

Light known as deep-UV with wavelengths ranging from 200 nm to 280 nm is useful for sterilization. In particular, it has been confirmed that 265 nm wavelength is most efficiently absorbed by the DNA of bacteria, sterilizing by modifying the DNA structure to render bacteria inactive and unable to reproduce, according to various studies. However, there are only a small number of LED manufacturers that produce 265 nm LEDs. This is because creating high power output is considered to be more difficult with 265 nm LEDs than with deep-UV LEDs with longer wavelengths of 275 nm to 285 nm. Deep-UV LEDs are still developing as light sources, and their light output is far less than that of ultraviolet lamps. For that reason, there are more LED manufacturers that prioritize high output with the more easily produced 275-285 nm range LEDs.

So why did Stanley continue to pursue development of a marketable 265 nm deep -UV LED if high output is more difficult to produce?

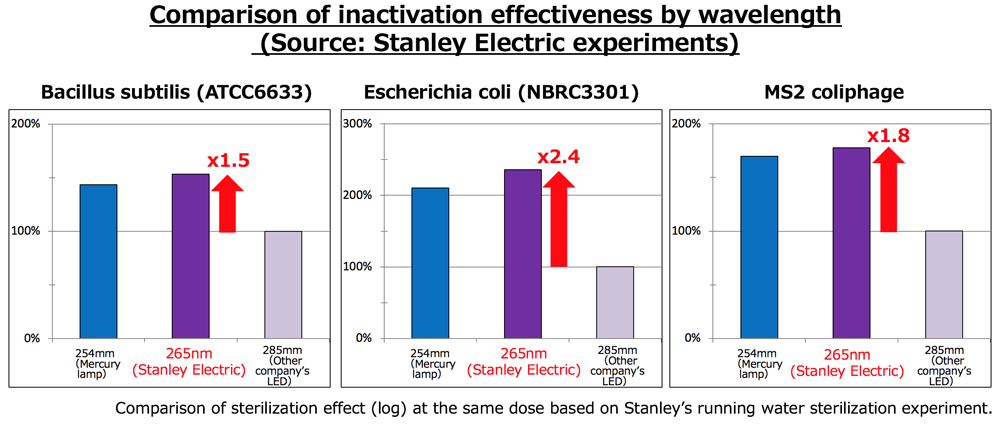

265 nm deep ultraviolet LEDs are efficient at disinfecting

There is an enormous difference in sterilizing capability between a wavelength of 265 nm and that of 285 nm. While it depends on the type of microorganism, experiments have shown that a wavelength of 265 nm is 2.4 times more effective at killing colon bacillus NBRC3301. Not only is a 265 nm deep-UV LED with 50 mW output more effective at disinfecting than a 285 nm deep-UV LED with 100 mW output, it consumes less power. Stanley has proprietary LED component manufacturing technology that makes high output possible at 265 nm, and the company has actually achieved an industry-leading output level of 50 mW at 265 nm. Stanley is continuing to work on development of even greater output and intends to lead the market for 265 nm deep-UV LEDs for sterilization applications.

With the development of a 265 nm deep-UV LED that is highly efficient at sterilization, sterilization applications using deep-UV rays are expected to greatly increase.

Until now, sterilization with deep-UV radiation has typically been done using ultraviolet lamps. However, although ultraviolet lamps can achieve a high light output, their use has been limited by their large size and short life span.

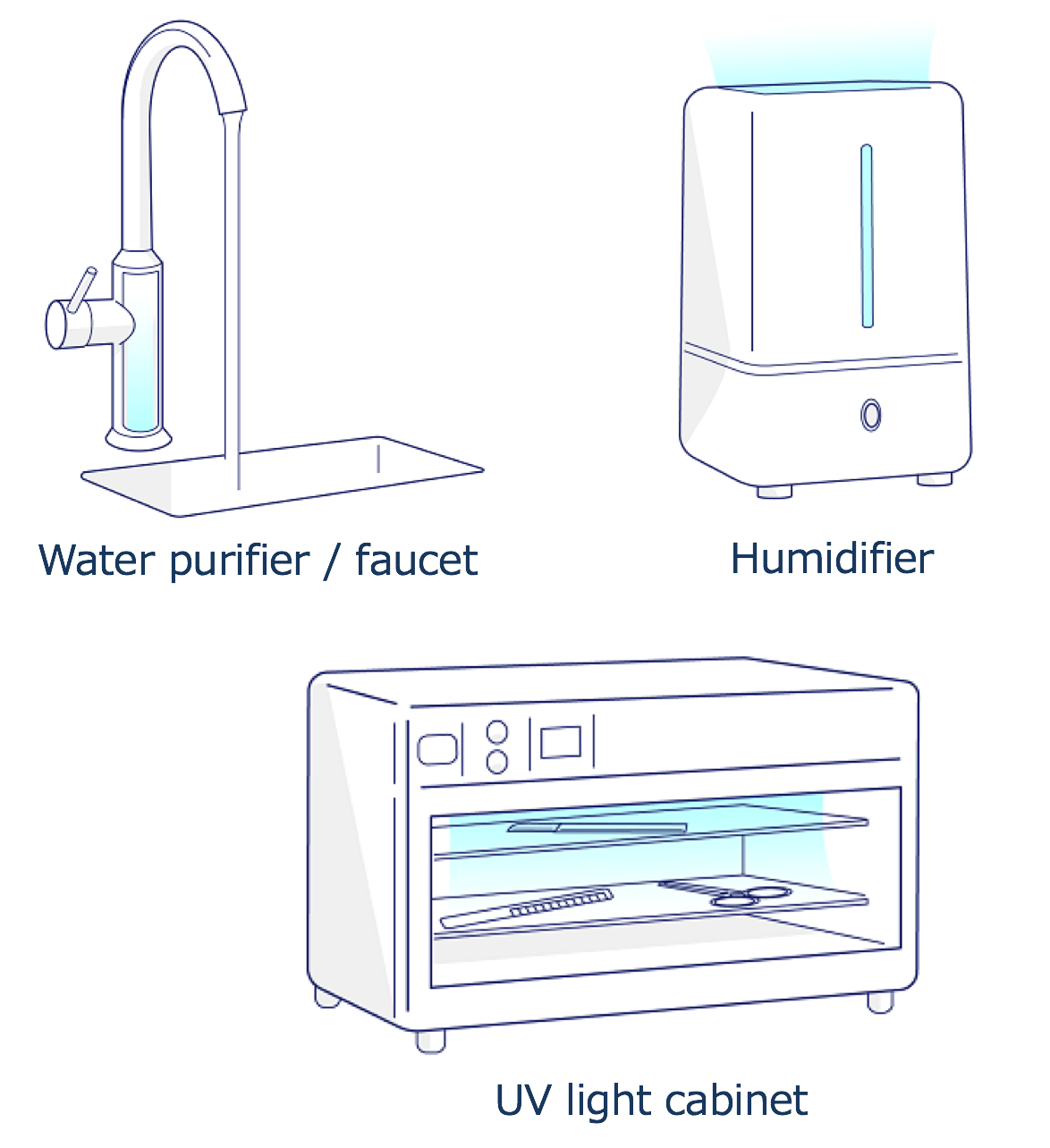

LEDs, on the other hand, are small, so they can be embedded in relatively small devices such as household water purifiers and humidifiers.

Ultraviolet lamps also include mercury, a substance that is damaging to the environment, making them subject to future regulation by the international Minamata Convention*. Ultraviolet lamps are currently exempt from regulation because there is no alternative, but their replacement with deep-UV LEDs in the near future is already being studied.

* Minamata Convention: A global treaty that regulates the manufacture, import and export of mercury and products that use mercury. The official name is Minamata Convention on Mercury. The treaty became effective in August of 2017.

Stanley has initiated a new project to promote and develop its environmental and sterilization business, and continues to challenge the business of sterilization with gas, liquid, and solid using UV light source.

Near ultraviolet LEDs hold promise in resin curing and deodorization applications

UVA (near ultraviolet light with wavelengths from 315 nm to 400 nm) LED technology is also advancing, with a wide new range of applications.

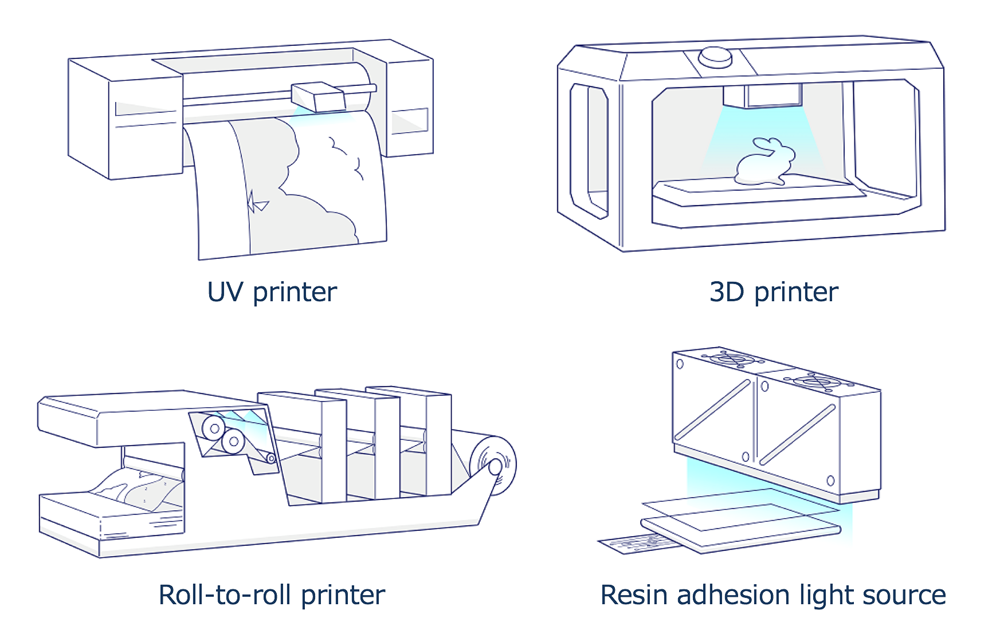

One typical use of near ultraviolet light by manufacturers of many industries is the curing of resin. In addition, near ultraviolet light is used as a light source for fluorescent inspection and for insect traps. In recent times, the new near ultraviolet LEDs have led to the development and wider use of UV printers and small scale 3D printers that use UV ink. Furthermore, near ultraviolet radiation of 387.5 nm and under activates photocatalysis of titanium dioxide (TiO2) and other elements, and its deodorizing effect when combined with photocatalysts is also noteworthy.

The market for near ultraviolet LEDs is large, as these LEDs are now widely used for a variety of applications, and demand is expected to increase markedly.

Stanley is meeting this increased demand for near ultraviolet LEDs with an abundant lineup of near ultraviolet LEDs that meet the needs of the market, including products with a middle power range of 950-1,100 mW and a high power range of 1,400-1,600 mW, each with wavelengths of 365 nm, 385 nm, 395 nm and 405 nm.

Also in the near ultraviolet LED market, there is strong demand for high power output, which leads to an increase in facilities performance and a reduction in the number of LEDs used. Stanley is responding to this demand by continuing to develop greater power output. In addition to high power output, demand for a longer operational life in order to reduce frequency of maintenance is high. Stanley also applies high heat dissipation package technology, a high reliability technology developed for automotive LED lights. Heat dissipation capacity is a factor that heavily impacts LED reliability, so that an efficient release of heat produced by the LED is needed. Stanley has applied high heat dissipation packages with a proven record in automotive applications to near ultraviolet LED products, achieving the industry’s top-class low thermal resistance of 3.0° C/W for products with a light output of 950 mW and 3.5° C/W for those with a light output of 1,400 mW at a wavelength of 365 nm. Furthermore, Stanley is beginning to apply hermetically sealed packaging technology to near ultraviolet LEDs to protect them from moisture and outgas. Although the current normal packaging structure without hermetic sealing maintains 70% of light output at 10,000 hours when operating at a normal temperature and maximum ratings, hermetically sealed packaging further extends LED life span.

These technologies give Stanley’s near ultraviolet LEDs greater output, a longer life span and greater reliability.

Demand increases for high power infrared LEDs as a sensor light source

LEDs that use the other invisible light - infrared - are also seeing increased demand in recent years.

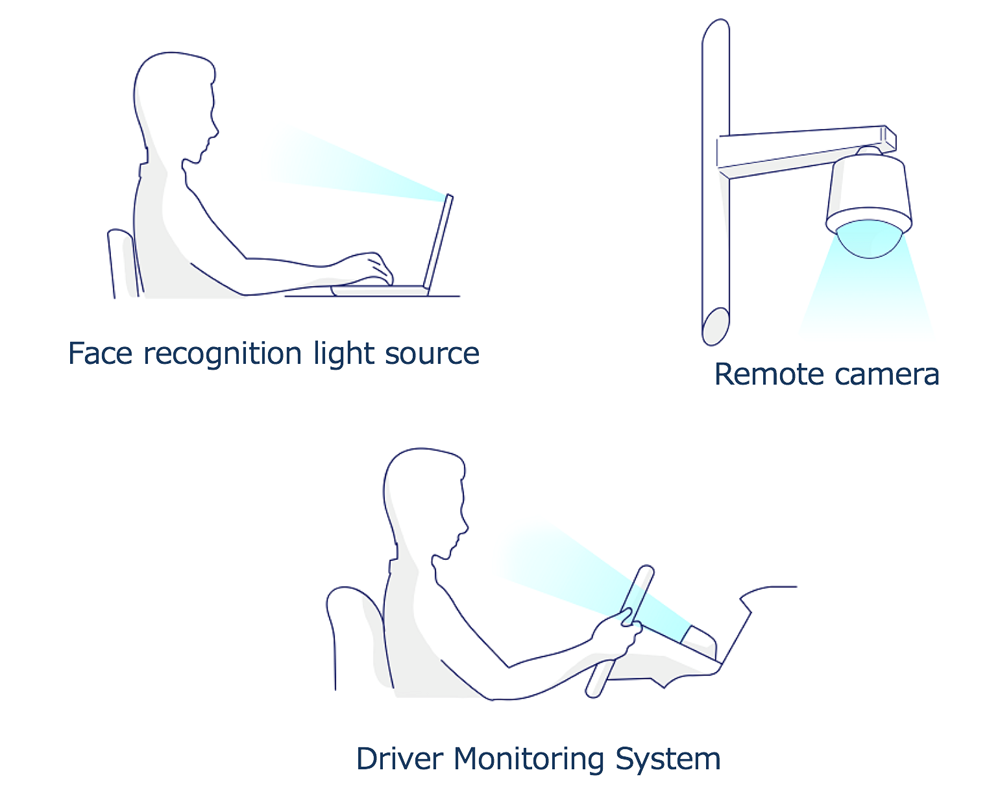

Unlike the more recent ultraviolet LEDs, infrared LEDs have a long history. Stanley began developing and marketing infrared LEDs in the 1970s. Infrared LEDs have been widely used in home appliance remote controls and infrared signaling systems. In recent years, increased demand for cameras has led to greater use of infrared LEDs as a supplemental light source.

Amid the increasing threat of crime and terrorism worldwide, security systems employing surveillance cameras are increasingly common. Even in Japan, where international events are held frequently, the pace of installation of these security systems is picking up rapidly, and the demand for infrared LEDs as a supplemental light source for surveillance cameras is increasing.

Similarly, remarkable strides have been made in autonomous driving systems for cars, and the demand for infrared LEDs as a sensor light source for the ever increasing number of onboard cameras and image sensors is growing. In particular, an application with rapidly increasing demand is the Driver Monitoring System (DMS) that monitors whether the driver is falling asleep and other driver states. Now frequently appearing in buses, taxis and trucks, the DMS takes an image of the driver from the front with an image sensor to monitor the driver’s state. Naturally, lighting is necessary to film in the dark with an image sensor, but the interior of the vehicle cannot be lit up for safety reasons. An infrared LED is therefore the perfect light source solution.

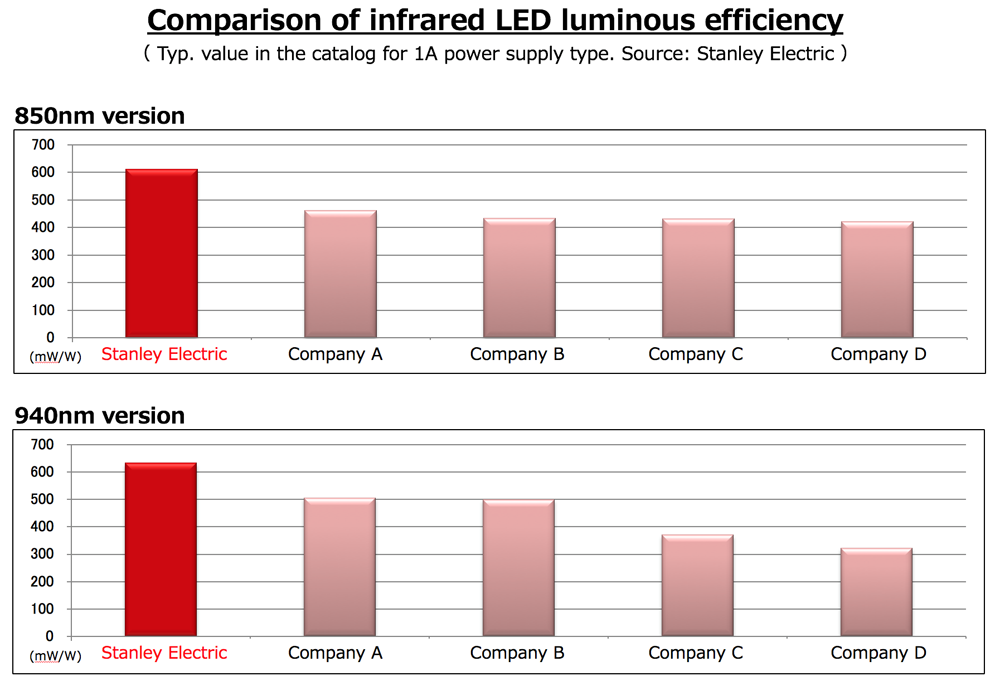

Stanley has been providing highly efficient, high power infrared LEDs for this increasingly sought after sensor light source. In October of 2017, Stanley began delivery of products with industry-leading luminous efficiency.

Among these is the MFN110□MS, which achieves an extremely high luminous efficiency of 633 mW output per input watt with a wavelength of 940 nm. The MGN110□MS, with a wavelength of 850 nm, has a luminous efficiency of 611 mW/W.

Furthermore, by using low forward voltage (Vf) LED components, Stanley keeps power consumption low, and with its proprietary low thermal resistance packaging, greatly reduces heat generation. Output of high power infrared LEDs, like that of other LEDs, drops in a high temperature environment, as does operational life span. In some cases, the LED may be destroyed under high temperatures. For that reason, LEDs need a heat sink or some other way to counter heat. Such heat management can be simplified by using new products with extremely low heat generation.

Wavelengths of 855nm (1100mW light output) and 945nm (950mW light output) are available, each with a directional half-value angle of 60° or 120°. The lineup consists of high-reliability package products that conform to automotive application quality, and black package products for surveillance cameras or other applications. Stanley’s infrared LED products are also characterized by package options for applications prioritizing reliability and those prioritizing cost.

Stanley states in the "Stanley Group Vision" that the company creates new benefits to humankind by dedicating it to the "Five Ways of Creating Value with Light".

Ultraviolet and infrared are invisible light but they hold the key to solving many modern-day problems. Stanley continues to contribute to society with its high output, highly reliable ultraviolet and infrared LEDs.

Wavelength Map

Wavelength Map Principles of UVC sterilization

Principles of UVC sterilization A comparison of sterilization effectiveness

A comparison of sterilization effectiveness Applications using deep ultraviolet (UVC) LEDs

Applications using deep ultraviolet (UVC) LEDs Applications using near ultraviolet (UVA) LEDs

Applications using near ultraviolet (UVA) LEDs High power UVA LEDs with hermetically sealed packaging

High power UVA LEDs with hermetically sealed packaging Primary applications using infrared LEDs

Primary applications using infrared LEDs Comparison of infrared LED luminous efficiency

Comparison of infrared LED luminous efficiency “Five Ways of Creating Value with Light”

“Five Ways of Creating Value with Light”