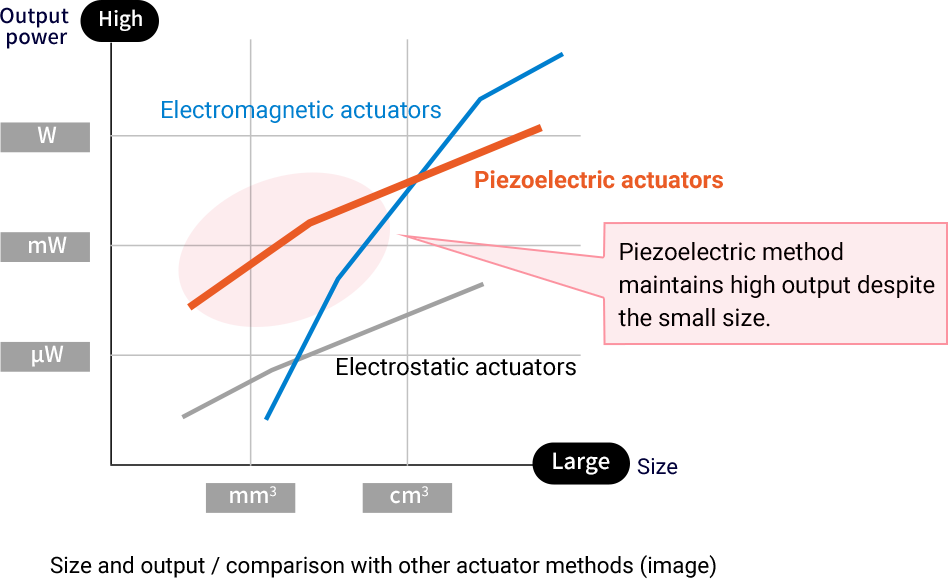

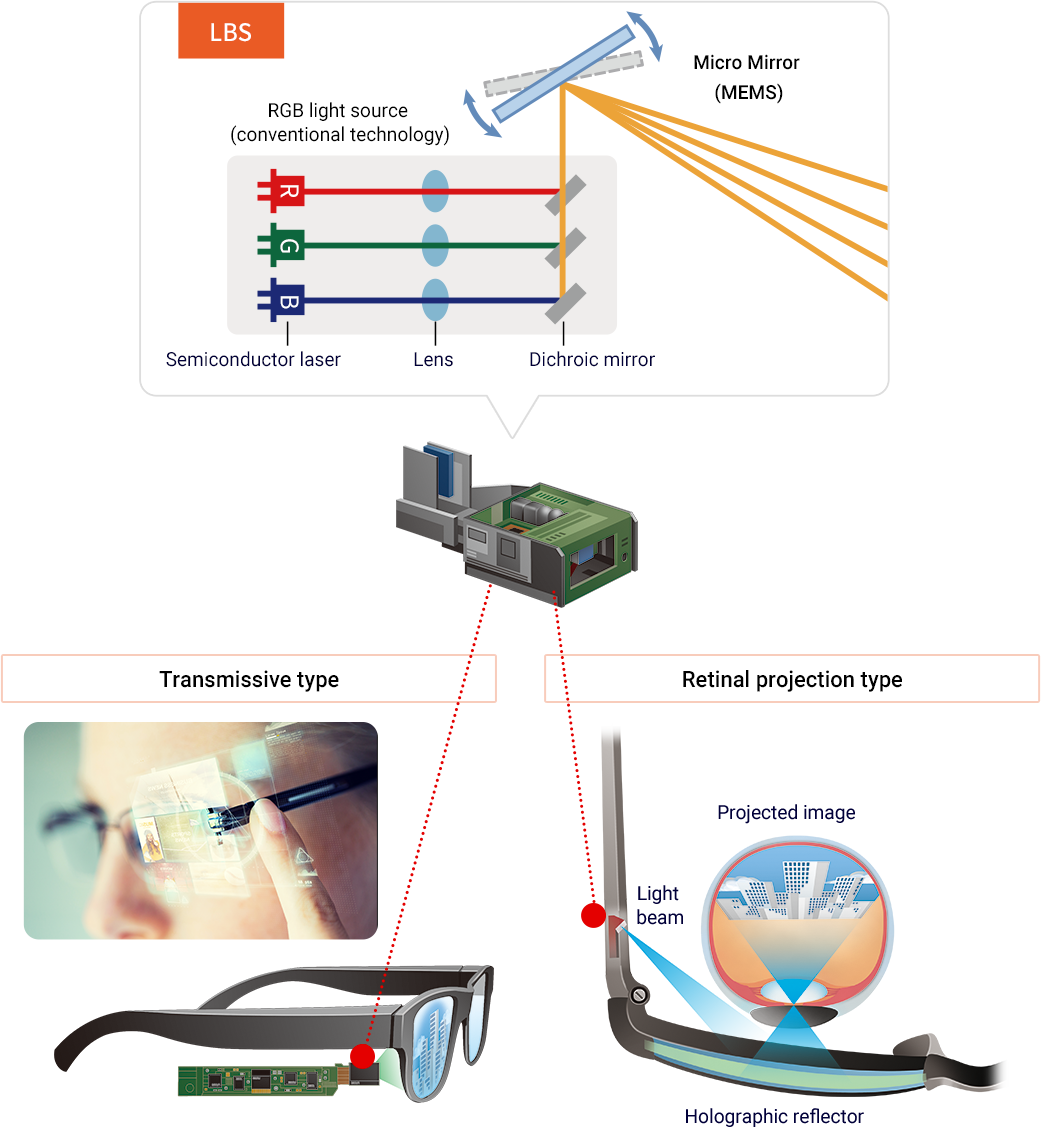

MEMS mirror is actuated by;

piezoelectric, electromagnetic, and electrostatic driving method.

MEMS

Scanning Mirror

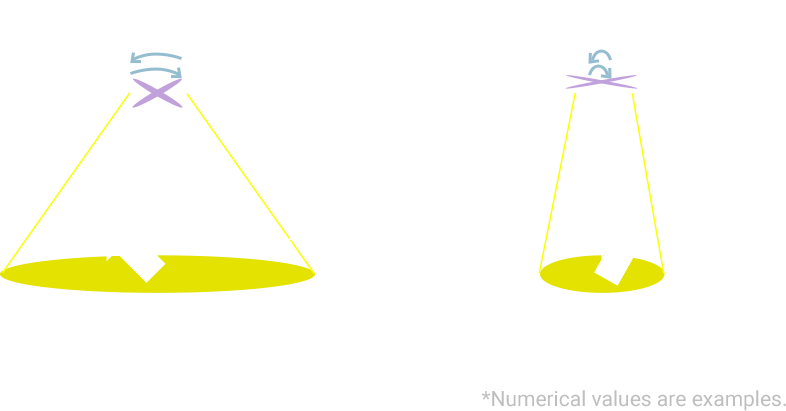

Downsizing: Output power of piezoelectric method becomes more superior as size decreases.

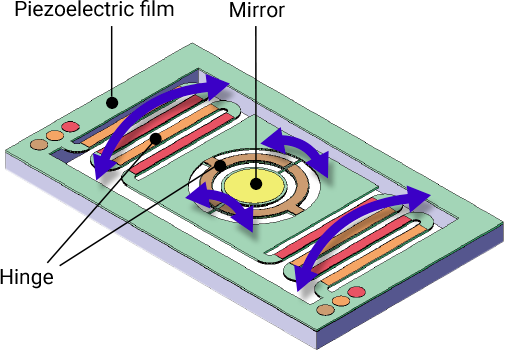

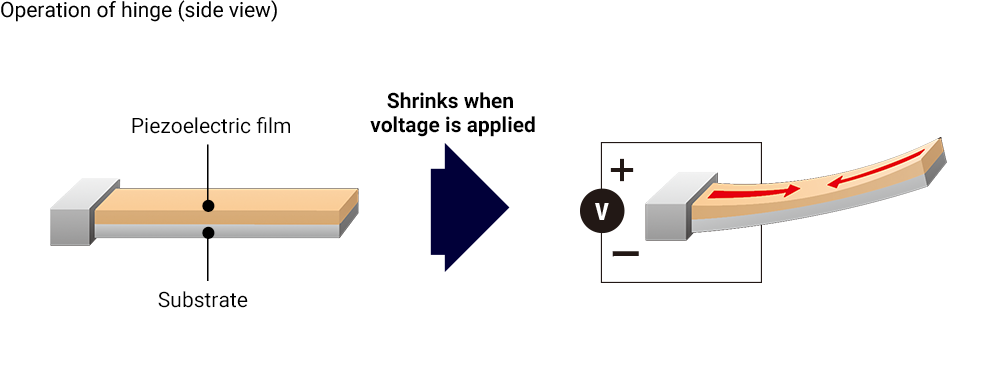

Stanley Electric's MEMS mirror is

applying the piezoelectric method.

Stanley Electric's MEMS mirror is

applying the piezoelectric method.

| Piezoelectric method | Electromagnetic method | Electrostatic method | |

| Device Appearance |  |

|

|

|---|---|---|---|

| Power per unit | ● High 106 - 107N/m2 |

△ Low 101 - 103N/m2 |

△ Low 101 - 104N/m2 |

| Operating environment temperature | ● Automotive qualified 125°C or lower |

× Non automotive qualified 100°C or lower |

● Automotive qualified 150°C or lower |

| Seismic Dynamic Resistance | ● Automotive qualified High |

● Automotive qualified High |

× Non automotive qualified Low |

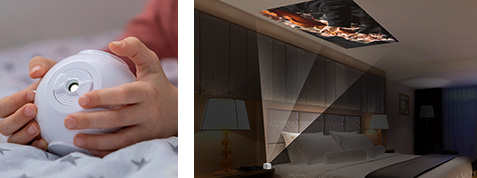

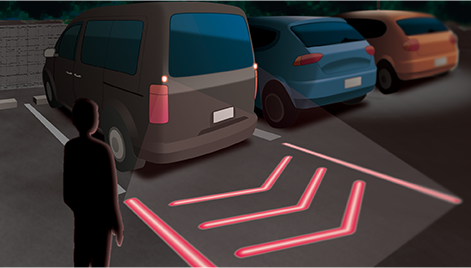

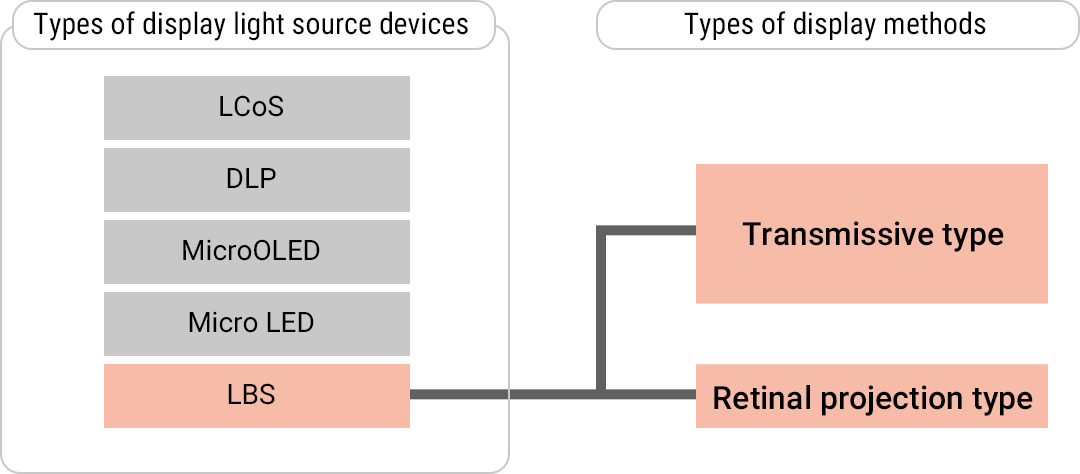

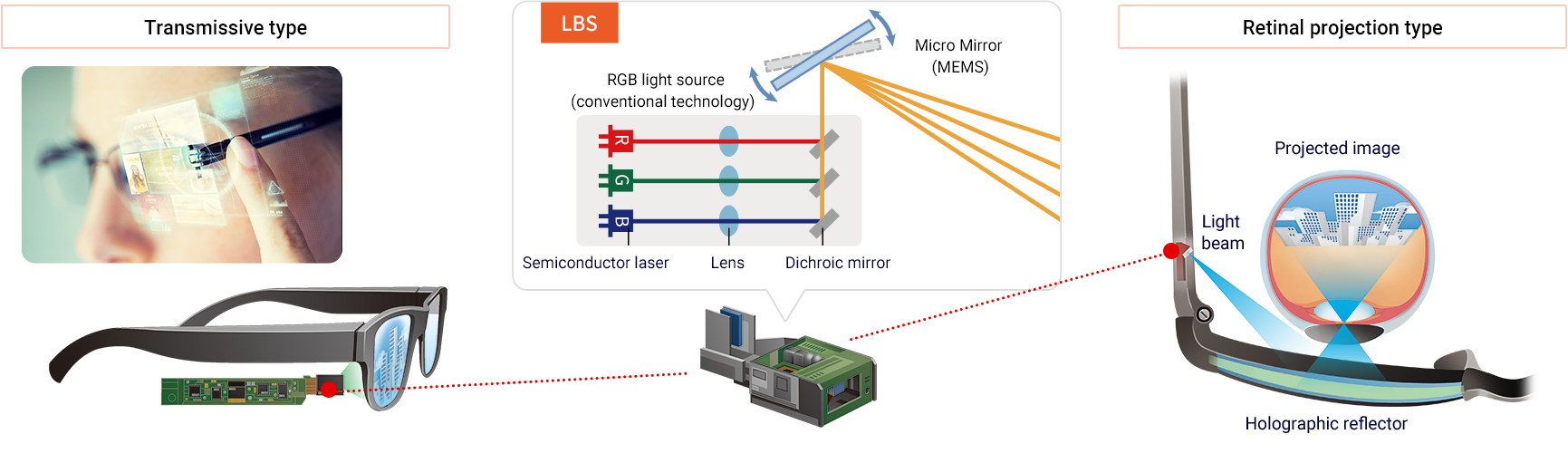

Applications where MEMS mirrors may be used include headlamps, intelligent lighting, mobile projectors, and AR glasses.

Headlamps

Headlamps Lighting

Lighting Projector

Projector Head Up Display

Head Up Display AR glass / Smart glass / Mobile devices

AR glass / Smart glass / Mobile devices Road projection lamp

Road projection lamp

| Model 1 | Model 2 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Parameter | Symbol | Data value | Data value | Unit | Remark | |||||

| Min | Typ. | Max | Min | Typ. | Max | |||||

| H-axis | Resonant Frequency | fh | 35 | 36.5 | 38 | 21 | 21.5 | 22 | kHz | |

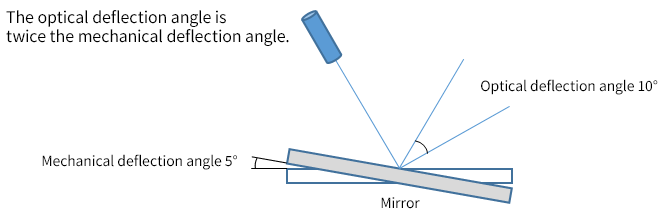

| Driving voltage | Vh | 11 | 13.6 | 17.3 | 9.9 | 13.5 | 18.8 | V | Sinusoidal wave (Resonance mode), at Maximum mechanical deflection angle | |

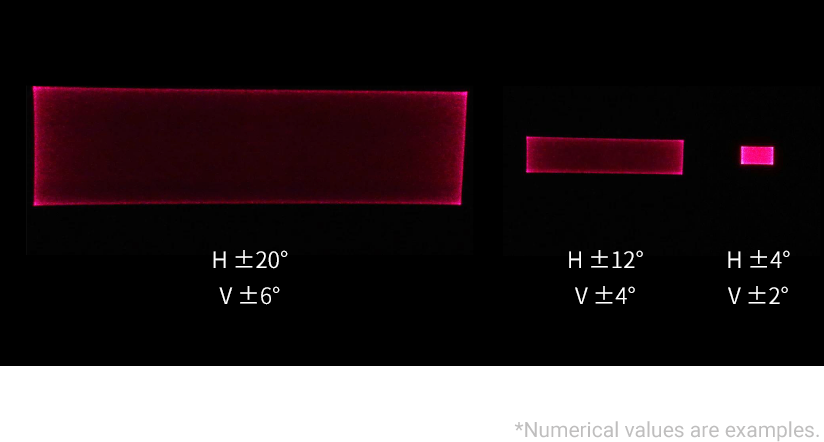

| Mechanical deflection angle | Θh | -11 | - | +11 | -10 | - | +10 | degree | ||

| V-axis | Resonant Frequency | fv | - | 736 | - | - | 1,074 | - | Hz | |

| Driving voltage | Vv | 41 | 52.3 | 63.5 | 35.7 | 47.1 | 58.5 | V | Sawtooth wave or Triangular wave (Non-resonant mode), at Maximum mechanical deflection angle | |

| Mechanical deflection angle | Θv | -6 | - | +6 | -3 | - | +3 | degree | ||

| Mirror | Size | A | Φ1.06 | Φ1.46 × 1.61 | mm | |||||

| Reflectivity B | Rb | 90 | - | - | 96 | - | - | % | 440-460nm | |

| Reflectivity G | Rg | 90 | - | - | - | - | - | % | 510-525nm | |

| Reflectivity R | Rr | 90 | - | - | - | - | - | % | 632-643nm | |

| Resolution | 1,219 x 840 | 1,164 x 467 | p | |||||||

| Metal package | Ceramic package | |||||||

|---|---|---|---|---|---|---|---|---|

| Parameter | Data value | Data value | Unit | Remark | ||||

| Min | Typ. | Max | Min | Typ. | Max | |||

| Incident angle of LD | 17.5 | 45 | degree | |||||

| Operating temperature | -40 | - | 125 | -10 | - | 70 | ℃ | No dew condensation |

| Storage temperature | -40 | - | 125 | -40 | - | 125 | ℃ | No dew condensation |

| Package size | 42.1 x 10 x 4.26 | 15.6 x 7.8 x 2.52 | mm | |||||

| Weight | 4.9 | 0.8 | g | |||||

We are available prototype products from the above lineup of 2 models and 2 packages, a total of 4 patterns.

Would you please feel free to contact us if you have any requests or questions.